Padanho remazuva ano indasitiri yekugadzira, CNC muchina maturusi ave musana wekugadzira nekugona kwavo uye kwakaringana kugadzirisa. Iwo machining echokwadi anodiwa ezvikamu zvakakosha zveyakajairwa CNC muchina maturusi pasina mubvunzo iwo epakati zvinhu zvinotaridza kusarudzwa kweiyo chaiyo level CNC muchina maturusi.

CNC muchina maturusi akaiswa muzvikamu zvakasiyana senge akapusa, anoshanda zvizere, uye ekupedzisira maturusi nekuda kwekushandisa kwavo kwakasiyana, uye nhanho dzehuchokwadi dzinosiyana zvakanyanya. Rakareruka CNC muchina maturusi achiri kutora nzvimbo mundima yazvino yema lathes uye milling muchina, ine kushoma motion resolution ye 0.01mm, uye kufamba uye machining kunyatsoita kunowanzo kubva 0.03 kusvika 0.05 mm kana pamusoro. Kunyangwe iko kurongeka kwacho kuri kushoma, mune mamwe machining mamiriro ayo chaiwo zvinodiwa zvisina kuomesesa, zviri nyore CNC muchina maturusi anoita basa risingadzoreki nekuda kwehupfumi hwavo uye kushanda kuri nyore.

Mukupesana kwakapinza, Ultra precision CNC muchina maturusi akagadzirirwa chaiwo machining anodiwa, nekurongeka kwekukatyamadza 0.001mm kana zvishoma. Ultra precision CNC muchina maturusi anowanzo shandiswa mune yakakwirira-chaiyo uye yekucheka-kumucheto minda senge aerospace nemidziyo yekurapa, ichipa yakasimba tsigiro yehunyanzvi yekugadzira yakanyanya kuomarara uye chaiyo inoda zvikamu.

Kubva pamaonero echokwadi, CNC maturusi emuchina anogona kukamurwazve kuita akajairwa uye nemazvo mhando. Kazhinji, pane makumi maviri kusvika makumi matatu ekuongorora zvinhu zveCNC muchina maturusi, asi akanyanya kuomesesa uye anomiririra iwo akisi imwe chete axis positioning kurongeka, imwe axis inodzokororwa yekumisikidza kurongeka, uye kutenderera kwechidimbu chebvunzo chinogadzirwa nemaviri kana anopfuura akabatana machining demo.

Kurongeka kwekumisikidza uye kudzokororwa kwekumisikidza kunoenderana uye pamwe chete kutsanangura iyo yakazara yekurongeka chimiro chezvinofambisa zvikamu zvemuchina chishandiso axis. Kunyanya maererano nekudzokorora kurongeka kwechokwadi, yakafanana negirazi, inonyatsoratidza kugadzikana kwekumira kweakisi pane chero nzvimbo yekumira mukati mekurohwa kwayo. Hunhu uhwu hunova hwaro hwekona hwekuyera kana shaft ichigona kushanda zvakatsiga uye nekuvimbika, uye yakakosha pakuona kushanda kwakasimba kwenguva refu kwechishandiso chemuchina uye kuenderana kwemhando yemuchina.

Yanhasi CNC system software yakafanana nemhizha yakangwara, ine hupfumi uye hwakasiyana-siyana hwekuripira mabasa, inokwanisa kudzoreredza nehungwaru kukanganisa kwehurongwa hunogadzirwa mune yega yekubatanidza cheni yekufambisa chikafu nemazvo uye zvakatsiga. Tichitora zvibatanidza zvakasiyana-siyana zveketani yekutumira semuenzaniso, kuchinja kwezvinhu zvakadai sekuchenesa, elastic deformation, uye kuoma kwekubatana hakusi nguva dzose, asi kunoratidza simba rekukurumidza kuchinja kwekuchinja kune zvakasiyana-siyana zvakadai sehukuru hwebasa rebasa rekushanda, kureba kwechinhambwe chekufamba, uye kukurumidza kwekufamba.

Mune mamwe akavhurika-loop uye semi akavharwa-loop feed servo masisitimu, iyo mechaniki yekutyaira zvikamu mushure meyeredhi yezvikamu zvakaita sengarava dzinoenda kumberi mumhepo nemvura, zvichienderana neakasiyana mutsaona zvinhu. Semuenzaniso, chiitiko chekupisa kwekurebesa kwebhora screws kunogona kukonzera kukukurwa munzvimbo chaiyo yekumisikidza yebhenji rebasa, nekudaro zvichiunza zvikanganiso zvakakura zvisingaite kune machining kururama. Muchidimbu, kana paine sarudzo yakanaka mukusarudza, hapana kupokana kuti iyo midziyo ine yakanakisa yakadzokororwa yekumisikidza kurongeka inofanira kuiswa pamberi, ichiwedzera inishuwarenzi yakasimba kuhutano hwekugadzirisa.

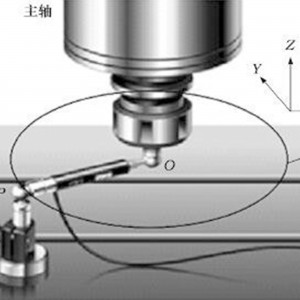

Iyo chaiyo yekugaya cylindrical nzvimbo kana milling spatial spiral grooves (tambo), senge mutongi wakanaka wekuyera kuita kwechishandiso chemuchina, chiratidzo chakakosha chekuongorora zvizere servo inotevera mafambiro maitiro eiyo CNC axis (maviri kana matatu axes) uye yekududzira basa remuchina weCNC system. Nzira inoshanda yekuona chiratidzo ichi ndeyekuyera kutenderera kweiyo yakagadziriswa cylindrical pamusoro.

Muchiito chekucheka zvidimbu zvebvunzo paCNC muchina maturusi, iyo milling oblique square mana mativi machining nzira inoratidzawo kukosha kwayo kwakasarudzika, iyo inogona kunyatso kutonga kuita kwekuita kwematemo maviri anodzoreka mumutsara wekududzira mafambiro. Paunenge uchiita iyi yekucheka oparesheni yekucheka, zvinodikanwa kunyatsoisa chigayo chekupedzisira chinoshandiswa kunyatso gadzira pamushini we spindle, uye wobva waita zvine hungwaru kugaya pane denderedzwa sampuli yakaiswa pabhenji rebasa. Kune madiki uye epakati-kati maturusi emuchina, ukuru hweiyo denderedzwa specimen inowanzosarudzwa pakati pe ¥ 200 uye ¥ 300. Iyi nhanho yakaedzwa mukuita uye inogona kunyatso ongorora machining akarurama emuchina mudziyo.

Mushure mekupedza kugaya, nyatsoisa mufananidzo wakachekwa pamita yeraundi woyera kutenderera kwenzvimbo yayo yakagadzirwa nemuchina uchishandisa chiridzwa chekuyeresa. Mukuita uku, zvinodikanwa kutarisa uye kuongorora zviyero zveyero zvine hunyoro. Kana paine zviripachena zvigayo cutter vibration mapatani pamilled cylindrical surface, inotiyambira kuti kukurumidza kupindira kwemuchina wemudziyo unogona kunge usina kugadzikana; Kana kutenderera kunogadzirwa nekugaya kunoratidza zvikanganiso zviri pachena zveelliptical, zvinowanzoratidza kuti zvakawanikwa zviviri zvinodzoreka axis masisitimu mukududzira mafambiro hazvina kunyatsoenderana; Kana paine zvibodzwa zvekumira pane yega yega inodzoreka axis mafambiro ekuchinja nzvimbo pane denderedzwa pamusoro (kureva, mukuenderera mberi kwekucheka mafambiro, kumisa mafambiro ekudya pane imwe nzvimbo kunoumba chikamu chidiki chesimbi yekucheka mamaki pane machining surface), izvi zvinoreva kuti kumberi nekudzokera kumashure kweaxis hakuna kugadziridzwa kune yakanakira mamiriro.

Pfungwa yeaxis imwe chete yekumisikidza kurongeka inoreva kukanganiso renji inogadzirwa pakumisa chero poindi mukati meiyo axis sitiroko. Yakafanana neimba yemwenje, inovhenekera zvakananga kugona kwemuchina wemuchina, uye nekudaro pasina mubvunzo ichiva imwe yeakanyanya kuomesesa tekinoroji zviratidzo zveCNC muchina maturusi.

Parizvino, pane mimwe misiyano mumirau, tsananguro, nzira dzekuyera, uye nzira dzekugadzirisa data dzeimwe axis chinzvimbo chechokwadi pakati penyika dzepasirese. Mukusuma kwakasiyana-siyana kweCNC muchina chishandiso chekuenzanisira data, yakajairika uye yakadudzwa zviyero zvinosanganisira American Standard (NAS), yakakurudzirwa zviyero neAmerican Machine Tool Manufacturers Association, German Standard (VDI), Japanese Standard (JIS), International Organisation for Standardization (ISO), uye Chinese National Standard (GB).

Pakati pezviyero izvi zvinokatyamadza, zviyero zveJapan zvakapfava maererano nemirairo. Iyo yekuyera nzira yakavakirwa pane imwechete seti yakagadzikana data, uyezve nehungwaru inoshandisa ± kukosha kudzvanya kukosha kwekukanganisa nehafu. Nekuda kweizvozvo, kurongeka kwenzvimbo kunowanikwa uchishandisa nzira dzekuyera dzeJapan dzinowanzosiyana nekanopfuura kaviri zvichienzaniswa nemamwe mazinga.

Kunyangwe mamwe mazinga achisiyana munzira yaanogadzirisa data, iwo akadzika midzi muvhu remhosho nhamba dzekuongorora uye kuyera kurongeka kwenzvimbo. Kunyanya, kune imwe nzvimbo yekumisikidza kukanganisa mune inodzoreka axis sitiroko yemuchina weCNC muchina, inofanirwa kuratidza zvikanganiso zvinogona kuitika muzviuru zvenguva yekumisikidza panguva yekushandiswa kwenguva refu kwechishandiso chemuchina mune ramangwana. Zvakadaro, zvakaganhurirwa nemamiriro chaiwo, isu kazhinji tinogona chete kuita nhamba shoma yekushanda panguva yekuyera, kazhinji kashanu kusvika kanomwe.

Iko kurongeka kwekutonga kweCNC muchina maturusi akafanana nerwendo rwakaoma rwekugadzirisa puzzle, haruna kuwanikwa nehusiku humwe. Zvimwe zviratidzo zvechokwadi zvinoda kunyatsoongororwa uye kuongororwa kwezvigadzirwa zvakagadziriswa mushure mekushanda kwekugadzirisa kwechigadzirwa chemuchina, izvo pasina mubvunzo zvinowedzera kuoma uye kuoma kwekutonga kwechokwadi.

Kuti tive nechokwadi chekusarudzwa kweCNC muchina maturusi anosangana nezvinodiwa zvekugadzira, isu tinofanirwa kuongorora zvakadzama maparamita ezvishandiso zvemuchina uye kuita ongororo yakazara uye yakadzama tisati taita sarudzo dzekutenga. Panguva imwecheteyo, zvakakosha kuve nekutaurirana kwakakwana uye kwakadzama uye kuchinjana neCNC muchina vanogadzira maturusi. Kunzwisisa danho rekugadzirwa kwemugadziri, kuomarara kwematanho ekudzora emhando, uye kuzara kwemashure-kutengesa sevhisi kunogona kupa hwaro hwakakosha hwekutarisa pakuita kwedu sarudzo.

Mumamiriro ekushandisa ekushandisa, iyo mhando uye nhanho yechokwadi yeCNC muchina maturusi anofanirwawo kuve nesainzi uye zvine musoro kusarudzwa zvichibva pane chaiwo machining mabasa uye nemazvo zvinodiwa zvezvikamu. Kune zvikamu zvine zvakanyanyisa kurongeka zvinodikanwa, maturusi emuchina akashongedzerwa nemhando yepamusoro CNC masisitimu uye yakakwirira-chaiyo zvikamu zvinofanirwa kutariswa zvakanyanya pasina kuzeza. Sarudzo iyi haingogadzirise kunaka kwekugadzirisa, asiwo inovandudza kugadzirwa kwekugadzira, inoderedza zvirahwe, uye inounza hupfumi hwepamusoro kune bhizinesi.

Uye zvakare, yenguva dzose yekunyatso kuyedza uye nekuchenjerera kuchengetedza kweCNC muchina maturusi matanho akakosha ekuona kwenguva refu yakagadzikana kushanda uye kuchengetedza yakakwirira-chaiyo machining kugona. Nekukurumidza kuziva uye kugadzirisa zvingangoitika nyaya dzechokwadi, hupenyu hwesevhisi hwematurusi emuchina hunogona kukwidziridzwa zvinobudirira, kuve nechokwadi kugadzikana uye kuvimbika kwemhando yemachina. Kungofanana nekutarisira yakakosha mota yemujaho, kungoramba kutarisisa uye kugadzirisa kunogona kuita kuti irambe ichiita zvakanaka panjanji.

Muchidimbu, iko kurongeka kweCNC muchina maturusi indekisi yakawanda uye yakazara yekutarisisa, iyo inomhanya kuburikidza nemaitiro ese emuchina dhizaini dhizaini nekusimudzira, kugadzira nekuunganidza, kuisirwa uye kugadzirisa, pamwe nekushandiswa kwezuva nezuva nekugadzirisa. Chete nekunyatsonzwisisa uye kugona ruzivo rwakakodzera uye tekinoroji tinogona kusarudza zvine hungwaru yakanyatsokodzera CNC muchina chishandiso mumabasa chaiwo ekugadzira, kubata zvizere mukugona kwayo kugona, uye kupinza simba rakasimba nerutsigiro mukusimudzira kwakasimba kweindasitiri yekugadzira.