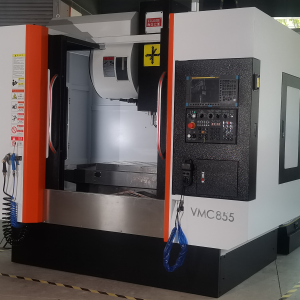

Muindasitiri yemazuva ano yekugadzira,CNC milling michinaave achishandiswa zvakanyanya nekuda kweakakosha mabhenefiti akadai seyakanyanya kurongeka, hunyanzvi hwepamusoro, uye dhigirii rekuita otomatiki. Nekudaro, kuti ushandise zvizere kuita kweCNC milling muchina uye kuwana yepamusoro-mhando uye inobudirira kugadzirisa, kusarudzwa kwekucheka maturusi kwakakosha. Sechikamu chakakosha chakanangana nekucheka, kusarudzwa kwakanaka kwekucheka maturusi kuchakanganisa zvakananga kunaka uye kugona kwekugadzira kwechigadzirwa chekupedzisira. Zvichienderana neizvi, chinyorwa ichi chinotarisa mune akakodzera mapoinzi ekusarudza chishandiso mukatiCNC milling michina.

1, Zvinodiwa zvekucheka maturusi muCNC milling muchina kugadzirisa

Nekuda kwekurongeka kwayo, kumhanya kwepamusoro, uye dhigirii re automation,CNC milling michinavakaisa mberi zvakaomesesa zvinodiwa zvezvishandiso zvinoshandiswa. Kuti ive nechokwadi chekugadzira machining uye nekuvandudza kugadzirwa kwakanaka, CNC milling muchina maturusi anofanirwa kuve neanotevera maitiro:

(1) Kuvimbika uye Kusimba

Chekutanga, maturusi ekucheka anofanirwa kuve nekuvimbika kwakanyanya uye kusimba. Mukuenderera mberi machining process yeCNC milling michina, chigadziro chinoda kumira zvakasimba-simba rekucheka masimba uye mitoro inopisa kwenguva yakareba. Kana kuvimbika kwechishandiso kusingakwane kana kusimba kwayo kwakadzikira, zviri nyore kusangana nematambudziko akadai sekupfeka nguva isati yakwana uye kudonha kwemupendero, izvo zvisingangokanganisa kunaka kwemuchina asiwo zvinotungamira kukuchinja kwezvishandiso kakawanda, kunowedzera kuderera kwekugadzira, uye kunoderedza kugona kwekugadzira. Naizvozvo, kusarudza maturusi emidziyo ane yakanaka kupfeka kuramba, kukanganisa kupikisa, uye kugadzikana kwemafuta, pamwe neane musoro dhizaini dhizaini, ndiyo kiyi yekuvandudza kuvimbika kwechigadzirwa uye kusimba.

(2) Kuoma uye kusimba

Kuti usangane nezvinodiwa zvekudzika kukuru kwekucheka uye kudya nekukurumidza panguva yakaoma machining, chishandiso chinofanira kuve nekuoma kwakanaka uye simba. Yakakura yekucheka kudzika uye nekukurumidza kudya kunogona kukonzera chishandiso kumirisana nehukuru hwekucheka masimba. Kana iyo kuoma kwechishandiso isina kukwana, inowanzoitika kune deformation, iyo inokanganisa machining kururama; Kusakwana kwesimba kunogona kukonzera kuputsika kwechishandiso uye kukonzera njodzi dzekuchengetedza. Nokudaro, mukugadzirwa kwezvishandiso nekugadzira, zviyero zvakadai sekugadzirisa chimiro chejometri chechigadziro uye kusarudza zvinhu zvine simba repamusoro zvinofanira kutorwa kuti ive nechokwadi chokuti chigadzirwa chacho chine kuoma kwakakwana uye simba.

(3) Chip kutyora uye kubvisa kuita

Yakanaka chip kutyora uye kubvisa kuita kwakakosha mamiriro ekuona kushanda kwakajairwa kwematurusi emuchina. Mukuita kweCNC kugaya, chizvarwa chinopfuurira uye kuunganidzwa kwemachipisi. Kana chishandiso chikatadza kutyora nekubvisa machipisi, zvinokonzeresa kuti machipisi aputire akatenderedza chishandiso kana workpiece, zvichikanganisa kugadzikana kwekucheka maitiro uye kunyange kukuvadza chishandiso nemuchina. Kuti uwane yakanaka chip kubviswa, iyo parameter yekucheka kumucheto chimiro, pamberi pekona, uye kumashure kwekona yechishandiso inofanira kunyatsogadzirwa. Panguva imwecheteyo, kusarudzwa kwakanaka kwekucheka ma parameter uye kushandiswa kwekucheka mvura kunogona kubatsirawo kuvandudza chip kubvisa maitiro.

(4) Kuisa nyore uye kugadzirisa

Iko kurerukira kwekumisikidzwa kweturusi uye kugadzirisa kwakakosha zvikuru mukuvandudza kugadzirwa kwekugadzira uye kuve nechokwadi chekuita machining. MuCNC milling muchina kugadzirisa, nekuda kwekugaro tsiviwa kwechishandiso uye kugadziridzwa kwechinzvimbo chechishandiso, kana kuisirwa kwechishandiso uye kugadzirisa maitiro kwakaoma uye kwakaoma, zvinopedza nguva yakawanda. Naizvozvo, maturusi ekucheka uye zvibatiso zvematurusi zvine chimiro chakareruka, kuisirwa kwakavimbika uye chinzvimbo, uye kugadzirisa kuri nyore kunofanirwa kusarudzwa kudzikisa kutsiva kwechishandiso uye nguva yekugadzirisa, uye kuvandudza mwero wekushandisa wemuchina.

(5) Yemhando yepamusoro yekucheka maturusi emidziyo

Kusarudza zvemhando yepamusoro zvekushandisa ndiyo hwaro hwekuvandudza mashandiro echishandiso. Parizvino, zvinowanzoshandiswa zvishandiso zvekushandisaCNC milling michinazvinosanganisira high-speed simbi, hard alloys, coated alloys, ceramics, cubic boron nitride, uye diamond. Zvishandiso zvakasiyana zvematurusi zvine maitiro akasiyana ekuita, uye akakodzera maturusi emidziyo anofanirwa kusarudzwa zvichienderana nezvinhu zvakaita sechinhu chebasa, tekinoroji yekugadzirisa, uye mamiriro ekucheka. Semuenzaniso, high-speed simbi yekucheka maturusi ane kusimba kwakanaka uye grindability, zvichiita kuti zvive zvakakodzera kugadzirisa zvikamu zvakaoma zvakaumbwa uye kucheka kwakaderera; Hard alloy yekucheka maturusi ane yakanyanya kuoma uye yakanaka kupfeka kuramba, ichiita kuti ive yakakodzera yekucheka-kumhanya uye rough machining; Zvishandiso zvekucheka zvakashongedzwa zvinowedzera kuvandudza mashandiro avo nekuputira nzvimbo yavo nekupfeka-inodzivirira uye yakakwirira-yekushisa inodzivirira coating, ichiita kuti ive yakakodzera kune akasiyana ekucheka mamiriro.

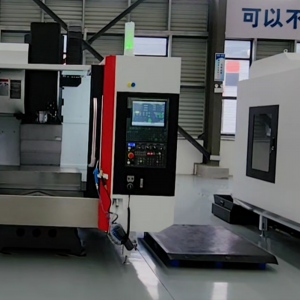

2, Kurongwa kweCNC milling muchina maturusi

Kune marudzi akasiyana-siyana eCNC milling muchinazvishandiso, izvo zvinogona kuiswa mumhando dzakasiyana zvichienderana neakasiyana emhando zviyero. Idzi dzinotevera idzo dzakajairika kupatsanurwa nzira:

(1) Yakakamurwa nechishandiso chimiro

Maturusi ekucheka akabatanidzwa

Integrated cutting tools inoreva zvishandiso izvo chikamu chekushanda uye shank inogadzirwa sese, zvakadai semagetsi ekupedzisira, drills, etc. Mushonga wekucheka wakabatanidzwa une chimiro chakareruka uye simba rakakwirira, asi rakaoma kugadzira uye rine mari yakakwirira. Inokodzera kugadzirisa zvikamu zvine maumbirwo akareruka uye yakakwirira chaiyo zvinodiwa.

Inlaid yekucheka midziyo

Maturusi ekucheka maturusi maturusi anorovera blade kana mazino pamutumbi wekucheka, senge mamill ekupedzisira, maturusi ekutenderedza, etc. Mashizha kana mazino emidziyo yakamisikidzwa yekucheka maturusi anogona kugadzirwa nezvinhu zvakasiyana uye maumbirwo ejometri kuti asangane nezvinodiwa zvakasiyana-siyana zvekugadzirisa, uye ave nemhando dzakasiyana-siyana uye hupfumi.

Mhando yakakosha yekucheka zvishandiso

Maturusi akakosha ekucheka maturusi anoreva maturusi akagadzirirwa kusangana nezvimwe zvakakosha zvekugadzirisa zvinodiwa, senge maturusi ekugadzira, maturusi emubatanidzwa, nezvimwe. Maturusi ekucheka akaumbwa anogona kugadzirisa pamusoro pezvikamu zvakaumbwa, senge gear milling cutters, spline milling cutters, nezvimwe; Composite yekucheka maturusi anogona kupedzisa akawanda ekugadzirisa matanho mune imwe yekucheka maitiro, senge kuchera uye kugaya composite yekucheka maturusi, anofinha uye kugaya anoumba composite yekucheka maturusi, nezvimwe.

(2) Kurongeka nemidziyo yekushandisa

High speed simbi yekucheka midziyo

High speed simbi imhando yesimbi yakakwira alloy ine huwandu hwakakosha hwealloying zvinhu zvakaita se tungsten, chromium, uye vanadium. Yekumhanyisa simbi yekucheka maturusi ane kusimba kwakanaka uye grindability, uye inogona kumira mikuru mikuru yekukanganisa. Izvo zvinowanzoshandiswa kugadzirisa zvikamu zvine maumbirwo akaoma uye yakakwirira chaiyo zvinodiwa, zvakadai sezvibooreso, matepi, zvigayo zvekucheka, etc. Maererano nekuita kwakasiyana-siyana, maturusi ekucheka simbi yepamusoro-soro anogona kukamurwa kuva-general-chinangwa-high-speed steel uye high-performance high-speed steel.

Universal high-speed simbi: Kuoma kwayo kunobva pa62 kusvika 69HRC, ine kumwe kusamira, simba rakawanda uye kuomarara, uye kumhanya kwekucheka kazhinji hakuna kukwira kupfuura 45 kusvika 60m/min, iyo isingakodzere kucheka kwekumhanya.

High performance high-speed simbi: Isimbi giredhi ine yakakwirira kupisa kupisa uye kupfeka kuramba kunowanikwa nekuwedzera zviri mukati kabhoni uye vanadium pahwaro hwesimbi inomhanya. Simbi yepamusoro-soro ine kuoma kwakatsvuka kwakanaka, uye inogona kuramba yakaomarara ye60HRC pa620-660 ℃. Kusimba kwayo ndeye 2-3.5 times iyo ye general-chinangwa chepamusoro-speed simbi. High performance high-speed simbi inowanzoshandiswa kugadzirisa zvakaoma kumichina zvinhu zvakadai sepamusoro-tembiricha alloys uye titanium alloys.

Hard alloy yekucheka zvishandiso

Hard alloy inogadzirwa nehupfu metallurgy process uchishandisa kuomarara kwakanyanya, high melting point metal carbides (senge tungsten carbide, titanium carbide, zvichingodaro) hupfu nemabhainda (senge cobalt, nickel, nezvimwewo). Hard alloy yekucheka maturusi ane maitiro ehukukutu hwepamusoro, kumira zvakanaka kupfeka, uye kupisa kwakanyanya kupisa, nekucheka kukurumidza kwe100-300m / min, yakakodzera kucheka-kumhanya uye rough machining. Hard alloy yekucheka maturusi anogona kuiswa mu tungsten cobalt (YG), tungsten titanium cobalt (YT), uye tungsten titanium tantalum (niobium) cobalt (YW) zvichienderana nekuumbwa kwavo uye kuita kwavo.

Tungsten cobalt (YG) yakaoma alloys: YG yakaoma alloys ine yakakwira cobalt yemukati uye yakanaka kuoma, ichiita kuti ive yakakodzera kugadzirisa brittle zvinhu senge simbi yakakandwa uye isiri-ferrous simbi.

Tungsten titanium cobalt (YT) yakaoma alloys: YT yakaoma alloys ane yakakwira titanium yemukati, yakanaka kuomarara uye kupfeka kuramba, uye akakodzera kugadzirisa zvinhu zvepurasitiki sesimbi.

Tungsten titanium tantalum (niobium) cobalt (YW) yakaoma alloy: YW yakaoma alloy inosanganisa zvakanakira YG uye YT yakaoma alloys, nehupamhi hwekuoma, kupfeka kusagadzikana, kupisa kupisa, uye kuomarara, kwakakodzera kugadzira zvinhu zvakasiyana-siyana, kunyanya kuoma kumichina zvinhu zvakaita sesimbi isina simbi uye inodzivirira kupisa simbi.

Coated kucheka midziyo

Zvishandiso zvekucheka zvakaputirwa zvakaputirwa nejira rekusapfeka-rinodzivirira uye yakakwirira-yepamusoro-yekudzivirira yekuvhara zvinhu, senge TiC, TiN, Al2O3, nezvimwewo, pamusoro peiyo yakaoma alloy kana yakakwirira-kumhanya simbi yekucheka maturusi. Maturusi ekucheka akavharwa anogona kuvandudza zvakanyanya kuoma kwepasi, kupfeka kuramba, uye kupisa kupisa kwekucheka maturusi, uye kuwedzera hupenyu hwavo hwesevhisi. Zvishandiso zvekucheka zvakaputirwa zvakakodzerwa nemamiriro akasiyana-siyana ekucheka, kunyanya kucheka kwepamusoro uye kutema kwakaoma.

Ceramic yekucheka zvishandiso

Ceramic yekucheka maturusi anonyanya kuumbwa neceramic zvinhu senge alumina (Al2O3) uye silicon nitride (Si3N4), iyo inonyungudika pakupisa kwakanyanya. Ceramic yekucheka maturusi ane zvakanakira senge kuomarara kwakanyanya, kunaka kupfeka kuramba, kupisa kwakanyanya, uye kugadzikana kwakanaka kwemakemikari. Iyo yekucheka inomhanya inogona kusvika 500-1000m / min, ichiita kuti ive yakakodzera ye-high-speed yekucheka uye yakanyatsogadzirwa machining. Nekudaro, maturusi ekucheka eceramic ane yakanyanya brittleness uye kushomeka kwekuita kuramba. Paunenge uchiashandisa, kutarisisa kunofanirwa kubhadharwa kudzivirira mitoro inokonzeresa.

Cubic boron nitride yekucheka maturusi

Cubic boron nitride (CBN) chinhu chakagadzirwa nepamusoro chakaoma uye nekuoma kwechipiri kune diamond chete. Cubic boron nitride yekucheka maturusi ane zvakanakira senge kuomarara kwakanyanya, kunaka kupfeka kuramba, kupisa kwakanyanya, uye kugadzikana kwakanaka kwemakemikari. Iyo yekucheka inomhanya inogona kusvika 1000-2000 m / min, ichiita kuti ive yakakodzera yekucheka-kumhanya uye kunyatsogadzira machining emhando dzakaoma zvinhu zvakadai sesimbi yakadzima uye chilled cast iron.

Diamond yekucheka maturusi

Dhaimondi ndicho chinhu chakaomesesa muzvarirwo, uye maturusi ekucheka madhaimani ane kuomarara kwakanyanya, kuramba kupfeka, uye kupisa kwemafuta. Iyo yekucheka inomhanya inogona kusvika 2000-5000m / min, ichiita kuti ive yakakodzera ye-high-speed yekucheka uye yakanyatsogadzirwa machining yezvinhu zvisiri zveferrous uye zvisiri zvesimbi. Nekudaro, maturusi ekucheka madhaimani anodhura uye haana kukodzera kugadzirisa simbi-yakavakirwa simbi zvinhu, sezvo madhaimondi achipinda kemikari maitiro nesimbi pakupisa kwakanyanya.

3, Kusarudzwa kwekucheka maturusi emidziyo yeCNC milling michina

Kune akasiyana marudzi ezvishandiso zvekushandisa zvinoshandiswa CNC machining, imwe neimwe iine yakasarudzika maitiro ekuita uye kushanda. Paunenge uchisarudza maturusi emidziyo, zvinodikanwa kunyatso funga zvinhu zvakaita senge zvinhu zvechishandiso, tekinoroji yekugadzira, mamiriro ekucheka, nezvimwe, kuitira kuti usarudze chakanyanya kukodzera chishandiso.

(1) Zviratidzo zvekushanda zvekucheka midziyo yekucheka simbi

Iyo yekucheka midziyo yekucheka simbi inowanzoda kuve neakatevedzana ekuita zviratidzo, pakati peiyo kuoma, simba, tsvuku kuoma, thermal conductivity, nezvimwe zvakanyanya kukosha.

Kuomarara ndiko kugona kwemidziyo yemidziyo kuramba kupfeka, uye iyo yakakwira kuomarara, ndiko kuwedzera kusagadzika chishandiso. Simba ndiko kugona kwezvishandiso zvekuramba kutyoka uye deformation, uye maturusi esimba akakwira anogona kumira akakosha ekucheka masimba. Tsvuku dzvuku inoreva kugona kwezvinhu zvekushandisa kuchengetedza kuomarara pakupisa kwakanyanya, uye zvishandiso zvine kunaka kwakatsvuka kuomarara zvakakodzerwa nekukasira kucheka. Thermal conductivity inokanganisa kupisa kwekupisa mhedzisiro yekucheka maturusi. Zvishandiso zvine yakanaka thermal conductivity zvinogona kukurumidza kutamisa kupisa kupisa uye kuderedza kupisa kupfeka kwezvishandiso.

(2) Yakanaka chishandiso zvinhu

Icho chakanakira chishandiso chinofanirwa kuve nekuoma uye kusimba, pamwe nekunaka kwakatsvuka kuomarara, kupisa conductivity, kupfeka kuramba, uye kuoma. Nekudaro, mune zvinoshanda zvekushandisa, zvakaoma kuwana chishandiso chinozadzisa zvizere zvese zvinodiwa, saka zvinodikanwa kuyera uye kusarudza zvinoenderana neakananga kugadzirisa mamiriro.

(3) Inowanzo shandiswa kucheka maturusi emidziyo mumashandisirwo anoshanda

Mukugadzirisa kunoshanda, alloy yakaoma uye yakavharwa yakaoma alloy yekucheka maturusi anonyanya kushandiswa nekuda kwekuita kwavo kwakazara kwekuita.

Hard alloy yekucheka maturusi ane yakanyanya kuoma uye kupfeka kuramba, izvo zvinogona kuenderana nezvinodiwa zvekumhanya-kumhanya kucheka uye rough machining. Yakavharidzirwa yakaoma alloy yekucheka maturusi, pahwaro hweakaomesesa alloy yekucheka maturusi, inowedzera kuvandudza mashandiro avo uye kuwedzera hupenyu hwavo hwebasa nekuapfekedza nedhiri yekupfeka-inodzivirira uye yakakwirira-yekushisa inodzivirira coating.

Kune zvimwe zvakaoma kumashini emidziyo, senge yakakwira-tembiricha alloys, titanium alloys, nezvimwe, cubic boron nitride yekucheka maturusi uye madhaimondi ekucheka maturusi ane zvakasarudzika. Cubic boron nitride yekucheka maturusi ane yakanyanya kuoma uye yakanaka yakatsvuka kuomarara, iyo inogona kunyatso kucheka yakakwirira kuomarara zvinhu; Maturusi ekucheka madhaimani ane kuomarara kwakanyanya uye kupisa kwemafuta, zvichiita kuti ive yakakodzera kune chaiyo machining yezvinhu zvisiri-ferrous uye zvisiri zvesimbi.

Kunyange zvazvo maturusi ekucheka-yepamusoro-soro asina kuoma uye asingasviki sematurusi ekucheka alloy, ivo vachiri nezvimwe zvikumbiro mukugadzirisa zvikamu zvakaoma zvakaumbwa uye kucheka kwakaderera nekuda kwekusimba kwavo kwakanaka uye grindability.

Ceramic yekucheka maturusi ane kuomarara kwakanyanya uye kwakanaka kupfeka kuramba, asi iwo ari brittle uye akakodzera kucheka-kumhanya kwekucheka uye kwakaringana machining.

4, Izvo zvinopesvedzera zvinhu zvekusarudzwa kwezvishandiso zve CNC milling michina

Pakusarudza CNC milling muchina maturusi, zvinotevera zvinhu zvinoda kunyatsotariswa:

(1) Chishandiso chemuchina

Mhando dzakasiyana-siyana uye tsanangudzo dzeCNC milling machines dzine maitiro akasiyana-siyana ekushanda, zvakadai sespindle speed, feed rate, simba, torque, nezvimwewo. Kusarudzwa kwekucheka maturusi kunofanira kufanana nekushanda kwechigadzirwa chemuchina kuti usunungure zvakakwana kukwanisa kwayo. Semuyenzaniso, kune yakakwira-kumhanya michina yekugaya, akakodzera ekucheka maturusi ekucheka-kumhanya anofanirwa kusarudzwa, senge akavharidzirwa maturusi akaoma alloy, maturusi e ceramic, nezvimwe; Kune emagetsi emagetsi ekugaya, maturusi ekucheka ane simba repamusoro uye kuomarara anogona kusarudzwa, senge akabatanidzwa akaomarara alloy yekucheka maturusi.

(2) Workpiece zvinhu

Kuitwa kwezvishandiso zvemaworkpiece kune zvakakosha pakusarudza chishandiso. Different workpiece zvinhu zvine kuoma kwakasiyana, simba, kuomarara, kupisa conductivity, etc. Semuenzaniso, kana uchigadzira brittle zvinhu zvakaita sesimbi yakakandwa, YG mhando yakaoma alloy yekucheka maturusi anogona kusarudzwa; Paunenge uchigadzira zvigadzirwa zvepurasitiki sesimbi, zvinokurudzirwa kusarudza YT mhando yakaoma alloy yekucheka maturusi kana yakavharwa yekucheka maturusi; Paunenge uchigadzira zvakaoma kumashini zvinhu zvakaita seyepamusoro-tembiricha alloys uye titanium alloys, cubic boron nitride yekucheka maturusi kana madhaimani ekucheka maturusi anoda kusarudzwa.

(3) Kugadzirisa chirongwa

Mhando yepurogiramu yekugadzira (yakadai seyakaoma machining, semi precision machining, precision machining) nekucheka zvigadziro (zvakadai sekucheka kukurumidza, chiyero chekudya, kucheka kudzika) kunokanganisawo kusarudzwa kwekucheka zvishandiso. Paunenge uchigadzira machining, maturusi ekucheka ane simba rakawanda uye kuomarara kunogona kumirisana nemasimba makuru ekucheka anofanirwa kusarudzwa, senge yakasimba yakaoma alloy yekucheka maturusi; Paunenge uchigadzira machini, maturusi ane hunyanzvi hwepamusoro uye mhando yakanaka yepamusoro inofanirwa kusarudzwa, senge yakavharwa yakaoma alloy maturusi kana maturusi e ceramic.

(4) Kucheka huwandu

Ukuru hwehuwandu hwekucheka hunogadzirisa zvakananga simba rekucheka nekucheka kupisa kunotakurwa nechishandiso. Paunenge uchigadzira nehombe huru yekucheka, midziyo yekucheka ine simba guru uye kunaka kwekudzivirira kupisa kunofanira kusarudzwa; Paunenge uchigadzira nezvidimbu zviduku zvekucheka, midziyo yekucheka nehupamhi hwekuoma uye kupfeka kwakanaka kwekudzivirira kunogona kusarudzwa.

5, Matanho uye nzira dzekusarudza maturusi ekucheka eCNC milling michina

Pakusarudza CNC milling muchina maturusi, anotevera matanho anogona kuteverwa:

(1) Sarudza kugadzirisa zvinodiwa

Chekutanga, zvinodikanwa kujekesa chimiro, saizi, chaizvo zvinodiwa, zvemhando yepamusoro zvinodiwa, uye maitiro ekugadzirisa (senge rough machining, semi precision machining, uye chaiyo machining) yezvikamu zvakagadziriswa.

(2) Ongorora zvinhu zveworkpiece

Ongorora mashandiro eiyo workpiece zvinhu, kusanganisira kuomarara, kusimba, kuomarara, kupisa conductivity, nezvimwe, kuona chakakodzera chishandiso.

(3) Sarudza rudzi rwechishandiso

Zvinoenderana nezvinodiwa zvekugadzirisa uye zvishandiso zvebasa, sarudza rudzi rwakakodzera rwechishandiso, senge zvigayo zvekupedzisira, zviboorero, zvinofinha zvinocheka, nezvimwe.

(4) Sarudza maturusi paramita

Sarudza dhayamita, kureba, nhamba yemapendero, helix angle, inotungamira angle, trailing angle, uye mamwe maparameter echishandiso chekucheka zvichienderana nekucheka maparamendi uye kuita kwemuchina.

(5) Sarudza kucheka maturusi mabhureki uye vatengesi

Mushure mekuona mhando uye zvimiro zvezvishandiso zvekucheka, sarudza mazita anozivikanwa uye vatengesi vanovimbika kuti ive nechokwadi chemhando yezvishandiso uye mushure mekutengesa sevhisi.

6, Kushandisa uye kugadzirisa CNC milling muchina maturusi

Kusarudza chishandiso chakakodzera ingori nhanho yekutanga, uye kushandisa kwakaringana nekuchengetedza chishandiso kwakakosha zvakaenzana pakuita kuti machining mhando uye kuwedzera hupenyu hwechishandiso.

(1) Kuiswa kwemidziyo yekucheka

Paunenge uchiisa chigadziro, zvakakosha kuve nechokwadi chekururama kwehutano pakati pechigadziro uye chigadziro chekushandisa, kuve nechokwadi chokuti chigadzirwa chacho chakasimba uye chakanyatsoiswa. Panguva imwecheteyo, kutarisisa kunofanirwa kubhadharwa kune yekumisikidza kutungamira uye chinzvimbo chezvishandiso kudzivirira zvikanganiso zvekuisa izvo zvinogona kukonzera kukanganisa machining kana kukuvara kwechishandiso.

(2) Kusarudzwa kwekucheka maparamendi ekucheka maturusi

Sarudzo inonzwisisika yekucheka paramita ndiyo kiyi yekuve nechokwadi chekucheka kwakajairwa uye kuwedzera hupenyu hwechishandiso. Kucheka maparamendi anosanganisira kukurumidza kucheka, chiyero chekudya, kudzika kwekucheka, nezvimwewo, uye inofanirwa kutariswa zvakazara zvichienderana nezvinhu zvakaita semidziyo yekushandisa, workpiece material, uye machining process. Kazhinji kutaura, mukati memhando inotenderwa yekucheka maturusi, kumhanya kwepamusoro kwekucheka uye madiki madiki ekudya anofanirwa kusarudzwa kuti avandudze machining kunyatsoshanda uye pamusoro pemhando.

(3) Kutonhora nekuzora zvekucheka maturusi

Munguva yekucheka, nzira dzakakodzera dzekutonhora uye dzekuzora dzinofanirwa kushandiswa kudzikisa tembiricha yekucheka, kuderedza kupfeka kwemidziyo, uye kunatsiridza kunaka kwenzvimbo yakagadzirwa. Yakajairika kutonhora uye nzira dzekuzora dzinosanganisira kucheka kutonhora kwemvura, kutonhora kwemhepo, mafuta mhute yekuzora, nezvimwe.

(4) Kuchengetedza uye kuchengetedza zvekucheka maturusi

Mushure mekugadzirisa, machipisi nemafuta emafuta pamidziyo yekucheka anofanira kucheneswa panguva yakakodzera, uye kupfeka kwezvishandiso kunofanira kuongororwa. Kana pane kupfeka, kunofanira kurodzwa kana kuchinjwa panguva yakakodzera. Panguva imwecheteyo, kugadzirisa nguva dzose kunofanira kuitwa pamidziyo yekucheka, yakadai sekushandisa mafuta ekudzivirira marara, kutarisa kurongeka kwechibatiso chekushandisa, nezvimwewo, kuve nechokwadi chekushanda uye hupenyu hwebasa rekucheka maturusi.

7, Mhedziso

Kusarudzwa kwematurusi ekucheka eCNC milling machine ibasa rakaoma uye rakakosha rinoda kutariswa kwakadzama kwezvinhu zvakawanda senge kuita kwemuchina, workpiece materials, machining programs, uye kucheka huwandu. Kusarudza uye kushandisa maturusi ekucheka nemazvo hakugone chete kuvandudza machining mhando uye kugona kwekugadzira, asi zvakare kuderedza mutengo wekugadzira uye kuwedzera hupenyu hwesevhisi yezvishandiso zvemuchina. Naizvozvo, mukugadzirwa chaiko, chishandiso chakakodzera kwazvo chinofanira kusarudzwa zvichibva pane chaiyo yekugadzirisa mamiriro uye maitiro echishandiso, uye mashandisiro uye manejimendi ekugadzirisa kwechishandiso kunofanirwa kusimbiswa kuti ikwidzise zvakanakira ma CNC milling muchina uye kupa rutsigiro rwakasimba mukusimudzira indasitiri yekugadzira.